Aerospace

Here at Pegrex, we have the versatility and expertise to work successfully for an incredibly wide range of clients. Our combination of engineering expertise, customer service and access to the latest technology means that we can meet demands for jobs ranging from one-off bespoke items to large batch industrial orders.

Our Aerospace Solution

We’re equally at home delivering projects for clients in the jewellery and giftware sectors as we are working for those in industries such as defence and aerospace.

Our work with aerospace clients is dependent upon our ability to deliver components to the highest possible tolerances. In a sector such as aerospace, it is both a legal requirement and a matter of life and death to work with components which are created to within fractions of millimetres. Our project management and consultancy experience means that we are able to work with aerospace clients on projects no matter what stage of development they have reached when they come to us.

For some clients, the component they need will still be at the earliest possible stage, such as a preliminary sketch or outline of an idea. Others come to us with a detailed plan already created, while some bring an existing component without a plan, and ask us to reverse engineer the component, analysing it in order to create a plan from which to reproduce it.

Have A Question? Get in touch:

How We Can Help

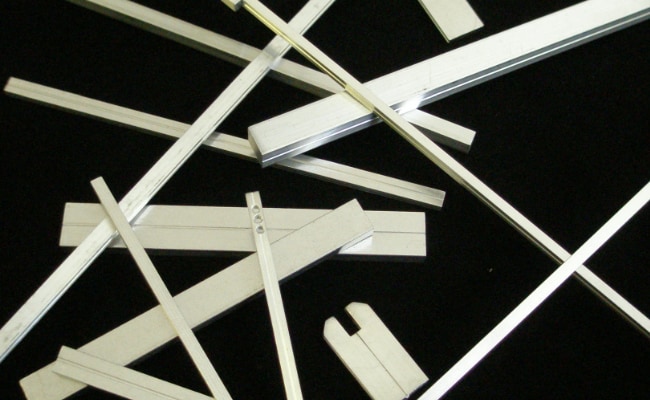

In all cases, we work in close partnership with the client in order to come up with a bespoke plan for delivery. The work we delivered for HS Marston Ltd. (HSM), one of our aerospace clients, is typical of the way in which we can utilise our skills and experience to deliver an incredibly broad range of projects. HSM manufactures heat exchangers for the aerospace industry, and they came to us because they wanted to reduce the cost of bought-in inventory and innovate in the manufacture of the parts. They also required full batch traceability on all the parts they use.

We visited them to fully evaluate their requirements, and as a result of our analysis, and based on our track record of component machining and finishing, we re-designed their component supply process completely.

One notable aspect of our solution was the fact that we utilised a combination of traditional machining techniques and our giftware finishing expertise to ensure that the components in question were accurate, precise and consistently free from burrs. As a result, HSM enjoyed an increase in component quality at the same time as cutting costs.

This is just one example of the solutions which we’re able to deliver, responding flexibly to clients who demand innovative thinking and a commitment to high quality.

Additional Information

Our credentials include the fact that we are a NATO certified components supplier and a BS EN ISO9001:2000 accredited company, having been BSI registered since 1992, and our unique combination of skills, experience and technology means we are ideally placed to deliver the kind of niche, highly specialised requirements that other providers often struggle with.

We’re located in the Midlands, close to the centres of the UK and the excellent local transport links enable us to offer a genuinely national service.

Our size and experience mean we can meet and deliver to extremely tight deadlines and respond quickly to client demand, up to and including offering limited production runs, just in time delivery and full batch traceability.

To enquire about our work in the aerospace sector or any of the other services we offer, simply call us on +44(0) 121 511 1475, send a fax to +44 121 511 1474 or email your enquiry to info@pegrex.co.uk.